The mechanical systems engineering department of Tohoku University and members of the Institute of Korea Photonics Technology have partnered to create a contact control system. The AI-driven system was developed to significantly cut down the consistent friction of the components in mechanical systems. This system is still undergoing tests in the laboratory. However, it could enhance the smooth running of different machines after the completion of the tests.

According to Professor Motoyuki Murashima of Tohoku University, the system could change the design pattern of machines from the conventional perspective of creating modern materials to developing exteriors that can conform in a way that will decrease the effect of friction. In addition to that, he also stated that the research will be the foremost ever to employ AI. This will help in effectively discovering parts in a mechanical system that the interaction of exteriors damages.

The research has focused on using resources that contain “morphing surfaces” that are flexible and can adapt to changes and the different environments in which the machine operates. Different groups of researchers have embarked on developing these materials by copying the standard features in flexible living things. For instance, the surface of leaves can adapt to changes in weather conditions.

New technology could help achieve a more refined control algorithm to prevent machine damage- Murashima

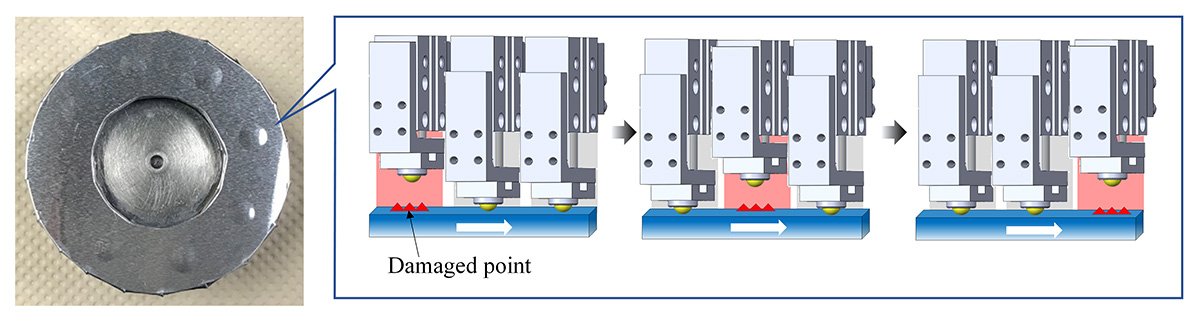

The researchers developed an AI method where detectors check and discover when there is friction between two exteriors. When the place of damage is discovered, this method will use the “morphing” role of the exterior to reduce the effect of friction within the affected parts significantly. The researchers have achieved a stable minimization of friction between the damaged regions of the resources. This was after analyzing and adjusting based on the experiment.

“An important next step is to develop more sophisticated learning and control algorithms that will reduce the time needed to learn the characteristics of the analyzed surfaces and therefore achieve more refined and speedier control that prevents damage.”

Professor Motoyuki Murashima , Department of Mechanical Systems Engineering, Tohoku University

The overall purpose of the contact control system is to enable a more significant number of mechanical systems to function effectively. This system would also reduce the need to replace parts of the machine. Ultimately, it will minimize wear and tear while increasing the useful life of the parts.

Photo credit: Motoyuki Murashima